| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : LHTi

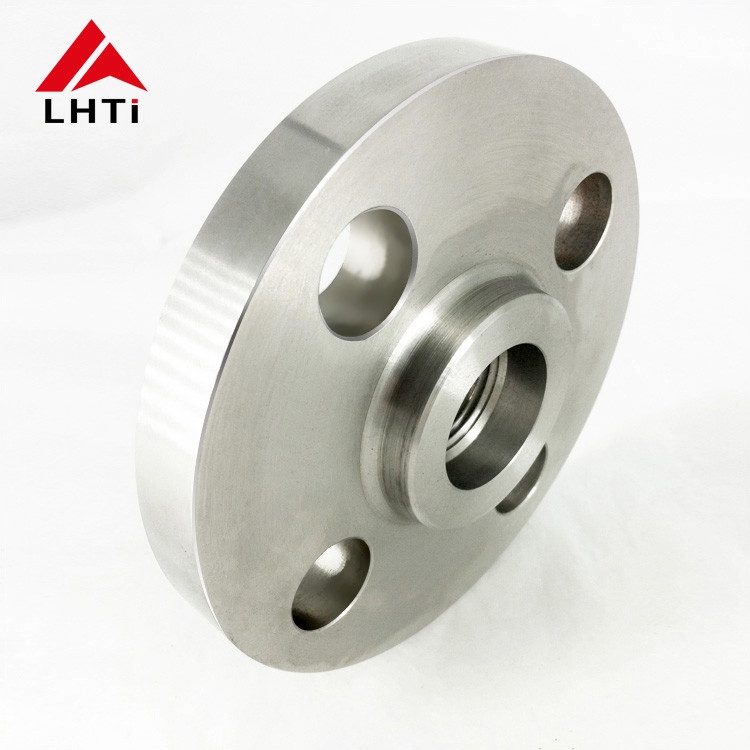

Model Number : Titanium Slip On Flange

Certification : ISO9001,CE,etc

Place of Origin : Baoji, Shaanxi, China

MOQ : 5 pieces

Price : negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union

Supply Ability : 5000 Pieces Per Month

Delivery Time : about 5-15 days for delivery

Packaging Details : Plywood case or pallet, or as per your requirement

Product Standard : ASME B16.5 Titanium Slip On Flange

Standard : ASME B16.5, ASME B16.47, EN 1092, DIN, JIS

Size : 1/2''to 24''

Pressure : Class 300

Features : High Strength, Corrosion Resistance, etc.

Surface Treatment : Pickled,sand blasting, rolling blast,galvinizing,vanished

Face Types : Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face

Materials : Gr1 Gr2 Gr5 Gr7 Gr12 etc.

Technology : colding forming ,hot working and welding

Application : Petroleum, Chemical, Power, Gas, Metallurgy, Shipbuilding, Construction, Etc.

ASME B16.5 Class 300 Titanium Plate Slip On Flange Ti Gr1 Gr2 Gr5 Gr7 Raised Face for Pipeline Industrial Applications

1.Product Introduction of ASME Titanium Plate Flange

Titanium flanges, crafted from titanium alloys, are highly valued across diverse industries for their exceptional properties. These flanges are renowned for their superb corrosion resistance, high strength-to-weight ratio, and lightweight nature. They excel in harsh environments where chemical corrosion is a concern, making them indispensable in industries such as petroleum, chemical processing, and others requiring robust material performance.

Key to their utility is titanium's innate resistance to corrosion, ensuring longevity and reliability in challenging operational conditions. Titanium flanges also exhibit excellent fatigue resistance and creep resistance, crucial for maintaining stable performance over extended periods. Their ease of machining and installation further enhances their appeal, providing practical solutions for various industrial applications.

ASME B16.5 Standard:

Scope: ASME B16.5 covers dimensions, tolerances, materials, marking, and testing for pipe flanges and flanged fittings.

Class 300: Class 300 flanges are designed to withstand higher pressures compared to Class 150. They are rated for pressures up to 300 pounds per square inch (psi) at ambient temperatures.

Titanium Grades:

Titanium Grade 2 (Ti Gr2): Commercially pure titanium (CP titanium) Grade 2 offers excellent corrosion resistance, formability, and weldability, making it suitable for various industrial applications where these properties are essential.

Titanium Grade 7 (Ti Gr7): Titanium Grade 7 contains palladium, enhancing its corrosion resistance in reducing and mildly oxidizing environments. It is particularly useful in chemical processing and marine applications.

Design Features:

Face Type: The blind flange may feature a raised face (RF), flat face (FF), or ring type joint (RTJ) facing to suit different sealing requirements.

Dimensions: ASME B16.5 specifies dimensions such as outside diameter (OD), bolt circle diameter (BC), bolt hole diameter (BH), and overall thickness (T) of the flange. These dimensions ensure compatibility and interchangeability with other ASME B16.5 flanges.

Applications:

Chemical Processing: Titanium Grade 2 and Grade 7 flanges in Class 300 are suitable for chemical processing industries where resistance to corrosive chemicals and high temperatures is crucial.

Oil and Gas: They find application in offshore platforms and refineries where exposure to seawater and harsh environments requires materials with excellent corrosion resistance.

Aerospace: These flanges are used in aerospace applications due to titanium’s lightweight properties, strength, and resistance to high temperatures.

Marine: In marine environments, titanium flanges are used in piping systems to resist corrosion from saltwater and maintain structural integrity.

Quality and Compliance:

Material Certifications: Manufacturers provide material certificates confirming compliance with specifications and standards, ensuring the quality and traceability of the titanium used.

Testing: Flanges undergo various tests such as ultrasonic testing (UT), hydrostatic testing, and dimensional inspections to ensure they meet specified requirements and performance standards.

2. Grades of ASME B16.5 Titanium Plate Slip On Flange Class 300

Grade 1 Titanium: Known for its high ductility, grade 1 titanium is the softest and most formable of all the commercially pure titanium grades. It's mostly used in applications that require superior corrosion resistance in environments such as the chemical processing industry.

Grade 2 Titanium: This is the most widely used titanium grade. It offers a good balance between strength and ductility, with excellent corrosion resistance. It is used in a broad range of applications, including flanges for piping systems.

Grade 5 Titanium (Ti 6Al-4V): This is an alloyed grade and the most commonly used of all titanium alloys. It significantly increases the strength of the flanges compared to pure titanium grades. Grade 5 titanium is used in high-strength applications where both heat and corrosion resistance are required.

Grade 7 Titanium: Featuring excellent weldability and fabricability, this grade includes palladium for enhanced corrosion resistance, particularly against reducing acids and localized attack in hot halides.

Grade 12 Titanium: This grade offers enhanced heat resistance and strength compared to other commercially pure grades. It also maintains good weldability and corrosion resistance.

Grade 23 Titanium (Ti 6Al-4V ELI): This grade is similar to Grade 5 but has extra low interstitials (ELI), making it preferable for higher fracture toughness and improved ductility. It's often used in medical applications and also suitable for flanges in critical, high-end applications.

| Chemical requirements | |||||||||||

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0. | |

3. Specifications for ASME B16.5 Calss 300 Titanium Slip On Flange

| Pipe |

Flange Data | Hub | Raised Face | Drilling Data | Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Pipe Size

| A | B | C | D | F | G | H | I | J |

kg/piece

| |

| Outside Diameter | Overall Diameter | Inside Diameter | Flange Thickness min | Overall Length | Hub Diameter | Face Diameter | Number of Holes | Bolt Hole Diameter | Diameter of Circle of Holes | ||

| in mm | in mm | in mm | in mm | in mm | in mm | in mm | in mm | in mm | |||

| 1/2 | 0.840 21.30 | 3.750 95.20 | 0.880 22.40 | 0.560 14.20 | 0.880 22.40 | 1.500 38.10 | 1.380 35.10 | 4 | 0.620 15.70 | 2.620 66.55 | 0.64 |

| 3/4 | 1.050 26.70 | 4.620 117.3 | 1.090 27.70 | 0.620 15.70 | 1.000 25.40 | 1.880 47.70 | 1.690 42.90 | 4 | 0.750 19.10 | 3.250 82.50 | 1.12 |

| 1 | 1.315 33.40 | 4.880 123.9 | 1.360 34.50 | 0.690 17.50 | 1.060 26.90 | 2.120 53.80 | 2.000 50.80 | 4 | 0.750 19.10 | 3.500 88.90 | 1.36 |

| 1 1/4 | 1.660 42.20 | 5.250 133.3 | 1.700 43.20 | 0.750 19.00 | 1.060 26.90 | 2.500 63.50 | 2.500 63.50 | 4 | 0.750 19.10 | 3.880 98.60 | 1.68 |

| 1 1/2 | 1.900 48.30 | 6.120 155.4 | 1.950 49.50 | 0.810 20.60 | 1.190 30.20 | 2.750 69.85 | 2.880 73.15 | 4 | 0.880 22.40 | 4.500 114.3 | 2.49 |

| 2 | 2.375 60.30 | 6.500 165.1 | 2.440 62.00 | 0.880 22.30 | 1.310 33.20 | 3.310 84.00 | 3.620 91.90 | 8 | 0.750 19.10 | 5.000 127.0 | 2.87 |

| 2 1/2 | 2.875 73.00 | 7.500 190.5 | 2.940 74.70 | 1.000 25.40 | 1.500 38.10 | 3.940 100.0 | 4.120 104.6 | 8 | 0.880 22.40 | 5.880 149.4 | 4.32 |

| 3 | 3.500 88.90 | 8.250 209.5 | 3.570 90.70 | 1.120 28.40 | 1.690 42.90 | 4.620 117.3 | 5.000 127.0 | 8 | 0.880 22.40 | 6.620 168.1 | 5.85 |

| 31/2 | 4.000 101.6 | 9.000 228.6 | 4.070 103.4 | 1.190 30.20 | 1.750 44.40 | 5.250 133.3 | 5.500 139.7 | 8 | 0.880 22.40 | 7.250 184.2 | 7.34 |

| 4 | 4.500 114.3 | 10.00 254.0 | 4.570 116.1 | 1.250 31.70 | 1.880 47.70 | 5.750 146.0 | 6.190 157.2 | 8 | 0.880 22.40 | 7.880 200.1 | 9.61 |

| 5 | 5.563 141.3 | 11.00 279.4 | 5.660 143.8 | 1.380 35.00 | 2.000 50.80 | 7.000 177.8 | 7.310 185.7 | 8 | 0.880 22.40 | 9.250 234.9 | 12.3 |

| 6 | 6.625 168.3 | 12.50 317.5 | 6.720 170.7 | 1.440 36.50 | 2.060 52.30 | 8.120 206.2 | 8.500 215.9 | 12 | 0.880 22.40 | 10.62 269.7 | 15.6 |

| 8 | 8.625 219.1 | 15.00 381.0 | 8.720 221.5 | 1.620 41.10 | 2.440 61.90 | 10.25 260.3 | 10.62 269.7 | 12 | 1.000 25.40 | 13.00 330.2 | 24.2 |

| 10 | 10.75 273.0 | 17.50 444.5 | 10.88 276.3 | 1.880 47.70 | 2.620 66.55 | 12.62 320.5 | 12.75 323.9 | 16 | 1.120 28.40 | 15.25 387.3 | 34.1 |

| 12 | 12.75 323.8 | 20.50 520.7 | 12.88 327.1 | 2.000 50.80 | 2.880 73.15 | 14.75 374.6 | 15.00 381.0 | 16 | 1.250 31.70 | 17.75 450.8 | 49.8 |

| 14 | 14.00 355.6 | 23.00 584.2 | 14.14 359.1 | 2.120 53.80 | 3.000 76.20 | 16.75 425.4 | 16.25 412.8 | 20 | 1.250 31.70 | 20.25 514.4 | 69.9 |

| 16 | 16.00 406.4 | 25.50 647.7 | 16.16 410.5 | 2.250 57.15 | 3.250 82.50 | 19.00 482.6 | 18.50 469.9 | 20 | 1.380 35.00 | 22.50 571.5 | 88.1 |

| 18 | 18.00 457.2 | 28.00 711.2 | 18.18 461.8 | 2.380 60.45 | 3.500 88.90 | 21.00 533.4 | 21.00 533.4 | 24 | 1.380 35.00 | 24.75 628.7 | 109 |

| 20 | 20.00 508.0 | 30.50 774.7 | 20.20 513.1 | 2.500 63.50 | 3.750 95.20 | 23.12 587.2 | 23.00 584.2 | 24 | 1.380 35.00 | 27.00 685.8 | 134 |

| 24 | 24.00 609.6 | 36.00 914.4 | 24.25 616.0 | 2.750 69.85 | 4.190 106.4 | 27.62 701.5 | 27.25 692.2 | 24 | 1.620 41.00 | 32.00 812.8 | |

4. Why We Choose Titanium Flanges in the Applications?

Titanium exhibits exceptional corrosion resistance, especially in aggressive environments such as seawater, chemical processing, and marine applications. This resistance to corrosion helps extend the lifespan of equipment and reduces maintenance costs.

Titanium has a high strength-to-weight ratio, making it significantly stronger than many other metals such as stainless steel or aluminum alloys while being much lighter. This property is crucial in aerospace, marine, and automotive industries where weight savings are critical.

Titanium is biocompatible and non-toxic, making it ideal for medical implants such as orthopedic implants and surgical instruments. It integrates well with the human body and minimizes the risk of adverse reactions.

Titanium retains its mechanical properties at elevated temperatures, making it suitable for applications where thermal stability is required. This includes aerospace components and industrial processes involving high heat.

Titanium has a low coefficient of thermal expansion, similar to stainless steel. This property helps maintain dimensional stability in various temperature conditions, ensuring reliability in critical applications.

Titanium is known for its durability and long service life, even in harsh operating conditions. This makes it a cost-effective choice over the long term, despite its higher initial cost compared to some other materials.

Titanium plate flanges are preferred in industries where their unique combination of properties is essential, such as aerospace, chemical processing, desalination plants, and offshore oil rigs.

5. Temperature Specifications for ASME B16.5 Titanium Slip On Flange

| ANSI B16.5 | Titanium Flanges Pressure Rating | ||||||

| Temperature °F | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

6. Packages of Titanium Slip On Flange

7.Different Face Types Of Titanium Plate Flanges:

Design:

Advantages:

Applications:

Design:

Advantages:

Applications:

Pressure and Sealing Requirements: Raised Face flanges are preferred for higher pressure applications where a reliable seal is critical. Flat Face flanges are suitable for lower pressure applications or where space constraints are a concern.

Gasket Selection: The choice of gasket (such as ring-type or full-face) depends on the flange facing type (RF or FF) and the application requirements for sealing integrity.

|

|

ASME B16.5 Class 300 Titanium Plate Slip On Flange Ti Gr1 Gr2 Gr5 Gr7 Raised Face for Pipeline Industrial Applications Images |