| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : LHTi

Model Number : Titanium Ball Valve

Certification : ISO9001,CE,etc

Place of Origin : Baoji, Shaanxi, China

MOQ : 5 pieces

Price : negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union

Supply Ability : 5000 Pieces Per Month

Delivery Time : about 7-14 days for delivery

Packaging Details : Plywood case or pallet, or as per your requirement

Model : Titanium Ball Valve

Pressure Rating : Class 150 Class 300

Actuator Type : Manual, Pneumatic, Electric

Grades : TA1 TA2 TA10 Gr2 Gr3

Operation Method : Lever, Gear, Actuator

Ball Material : Titanium

Design Standard : API 6D, ASME B16.34

Bore Type : Full Bore, Reduced Bore

Anti-Static Design : API 608

Fire Safe Design : API 607, API 6FA

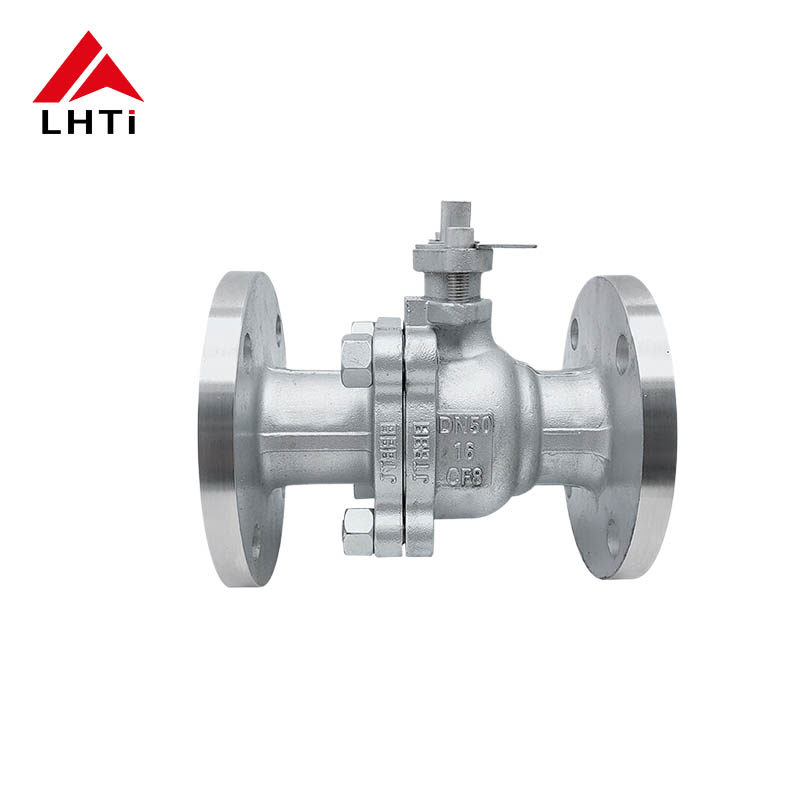

ANSI Titanium Ball Valve TA1 TA2 TA10 Gr2 Gr3 Class 150 Class 300 2 Inch Ball Valve in Oil and Gas Industry

Introduction of Titanium Ball Valve:

Special material valves are designed to meet specific requirements in various industries where standard materials may not be suitable due to corrosive or extreme operating conditions. Here is the introduction of special material valves in English:

Special material valves are specifically designed to handle challenging environments and demanding applications where standard materials may not suffice. These valves are crafted from high-performance alloys or specially engineered materials to provide superior corrosion resistance, high temperature tolerance, and exceptional durability.

Titanium ball valves are a type of valve used in special processes and environmental conditions. Due to the excellent corrosion resistance and high strength of titanium alloys, titanium ball valves find widespread application in industries such as chemical processing, marine engineering, and aerospace. Based on their structure and function, titanium ball valves can be categorized into different types, each with specific advantages and applications.

Titanium ball valves are essential for diverting, mixing, or altering the flow direction of fluids. They are engineered with a top-mounted structure that minimizes the number of connecting bolts in the valve body, particularly beneficial under high-pressure and large-diameter conditions. This innovative design not only improves the valve's reliability but also mitigates the influence of the system's weight on the valve's normal operation.

Product Specifications:

| Product Technical Specifications: | |

| Pressure Rating: | PN1.6-4.0Mpa Class150-300Lb |

| Nominal Diameter: | DN15-DN300 1/2"-12" |

| Drive Mode: | Handle, Worm Gear, Pneumatic, Hydraulic, Electric |

| Body, Bonnet: | TA1,TA2,TA10,Gr2,Gr3 |

| Ball: | TA1,TA2,TA10,Gr2,Gr3 |

| Stem: | TA1,TA2,TA10,TC4,Gr2,Gr3,Gr5 |

| Sealing Ring: | PTFE,RPTFE,PPL,PEEK |

| Titanium Ball Valve Model: | Q44F-16Ti,Q44F-25Ti,Q44F-40Ti,Q45F-16Ti,Q45F-25Ti,Q45F-40Ti,Q344F- 16Ti,Q344F-25Ti,Q344F-40Ti,Q345F-16Ti,Q345F-25Ti,Q345F-40Ti,Q644F-16Ti, Q64F-25Ti,Q644F-40Ti,Q645F-16Ti,Q645F-25Ti,Q645F-40Ti,Q944F-16Ti,Q944F- 25Ti,Q944F-40Ti,Q945F-16Ti,Q945F-25Ti,Q945F-40Ti,Q44F-150LB(Ti),Q44F- 300LB(Ti),Q345F-150LB(Ti),Q645F-150LB(Ti),Q945F-150LB(Ti) |

| Design Standards: | GB/T12237,ASME B16.34 |

| Face-to-Face Dimensions: | GB/T12221,ASME B16.10 |

| Flange Connections: | HG,GB,JB,API,ANSI,ISO,BS,DIN,NF,JIS |

| Testing Standards: | JB/T9092,GB/T13927,API598 |

Features of Titanium Ball Valve:

The ball of a titanium ball valve is floating. Under the action of medium pressure, the ball can produce a certain displacement and press tightly against the sealing surface of the outlet end to ensure the sealing of the outlet end. The main advantage of the American Standard titanium ball valve is that it utilizes the excellent stability and self-passivation capability of the oxide film formed on titanium metal in highly corrosive environments, allowing it to resist strong corrosion in various harsh working conditions.

Low Flow Resistance: Ball valves have relatively low fluid resistance among all valve types. Even for reduced bore ball valves, the fluid resistance is quite small.

Good Sealing Performance: The sealing performance of American Standard titanium ball valves is excellent. The valve seat (sealing ring) is generally made of elastic materials such as PTFE (polytetrafluoroethylene), which ensures sealing easily. Moreover, the sealing force of the ball valve increases with the pressure of the medium.

Reliable Stem Sealing: The stem of a ball valve only rotates 90° during opening and closing operations, so the packing seal of the stem is not easily damaged. Additionally, the sealing force of the reverse seal of the stem increases with the pressure of the medium.

Applications of Titanium Ball Valves:

Titanium ball valves have a wide range of applications in various industrial fields, mainly including the following aspects:

Chemical Industry: Due to the excellent corrosion resistance of titanium materials, titanium ball valves are commonly used in chemical production processes that involve handling corrosive media, such as acid and alkali solutions, and oxides.

Petroleum and Natural Gas Industry: Titanium ball valves play a crucial role in the extraction, transportation, and processing of petroleum and natural gas. They are used to control the flow and pressure of fluids, ensuring the safe and stable operation of the system.

Marine Engineering: Titanium ball valves have good seawater corrosion resistance, making them widely used in marine engineering applications, such as fluid control systems in subsea pipelines and offshore platforms.

Aerospace Field: Titanium ball valves are extensively used in aerospace hydraulic systems, fuel systems, etc., due to their lightweight and high-strength characteristics that meet the requirements of aircraft.

Food and Pharmaceutical Industries: Since titanium materials are non-toxic and do not contaminate food or medicine, titanium ball valves are often used in fluid control systems in food processing and pharmaceutical industries.

|

|

ANSI Titanium Ball Valve Gr2 Gr3 Class 150 Class 300 2 Inch Ball Valve In Oil And Gas Industry Images |